SOMFY CB 230 RTS Control Module

The SOMFY CB230 RTS Control Module ensures efficient gate management with advanced features like soft stop, torque adjustment, and easy remote pairing. Designed for the IXENGO L 230V RTS, it offers a weather-resistant build (IP44) and energy efficiency, making it perfect for residential and commercial gate systems.

د.إ850

In Stock

The SOMFY CB230 RTS Control Module is a precision-engineered solution for managing gates with the IXENGO L 230V RTS system. Offering advanced control features, such as soft stop, torque adjustments, and easy remote pairing, this module ensures smooth and efficient gate operation. It’s an ideal choice for Abu Dhabi’s residential and commercial properties.

Key Features

Advanced Safety Functions: Built-in safeguards for gate operation, including soft stop and torque adjustments.

User-Friendly Setup: One-key self-learning and easy pairing for remote controls simplify installation.

Customizable Settings: 12 switches for advanced configurations to match your specific needs.

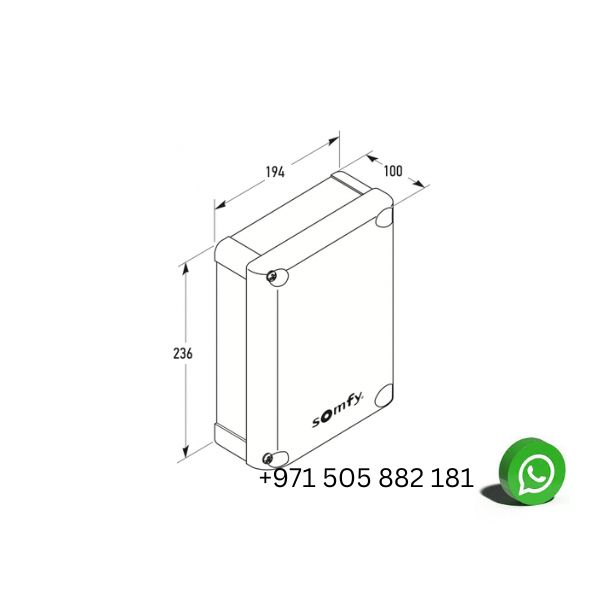

Compact Design: Dimensions of 194 x 236 x 100 mm ensure compatibility with most gate setups.

Durable Construction: Rated IP44, designed for outdoor use in challenging climate.

The SOMFY CB230 RTS Control Module is designed to handle extreme weather conditions while maintaining reliable performance. Operating at a standard 230V with minimal energy consumption (210 W), it’s efficient and long-lasting, making it suitable for high-traffic areas or demanding environments.

Why Choose?

– Enhances gate safety with precise torque and soft stop settings.

– Quick and easy installation with intuitive programming.

– Weather-resistant build ensures consistent performance outdoors.

– RTS technology offers seamless remote operation with a range of 433.42 MHz.

Transform your gate system with this RTS Control Module, offering unmatched efficiency, safety, and durability. Perfect for unique requirements, it’s an essential upgrade for modern automation. For more advanced control solutions, visit Nice Automation Systems.