Loading Dock Door Repair Guide: AI, Sensors, and Smarter Operations

Loading dock doors are the heartbeat of warehouses and logistics hubs. If they fail, supply chains slow, costs rise, and safety is compromised. By 2025, dock maintenance challenges have become more complex due to heavier workloads and rising customer expectations. The good news? AI, IoT sensors, and smart automation are transforming repair processes into proactive, efficient systems. The global warehouse automation market alone is growing at more than 12% annually , showing how fast facilities are embracing these technologies.

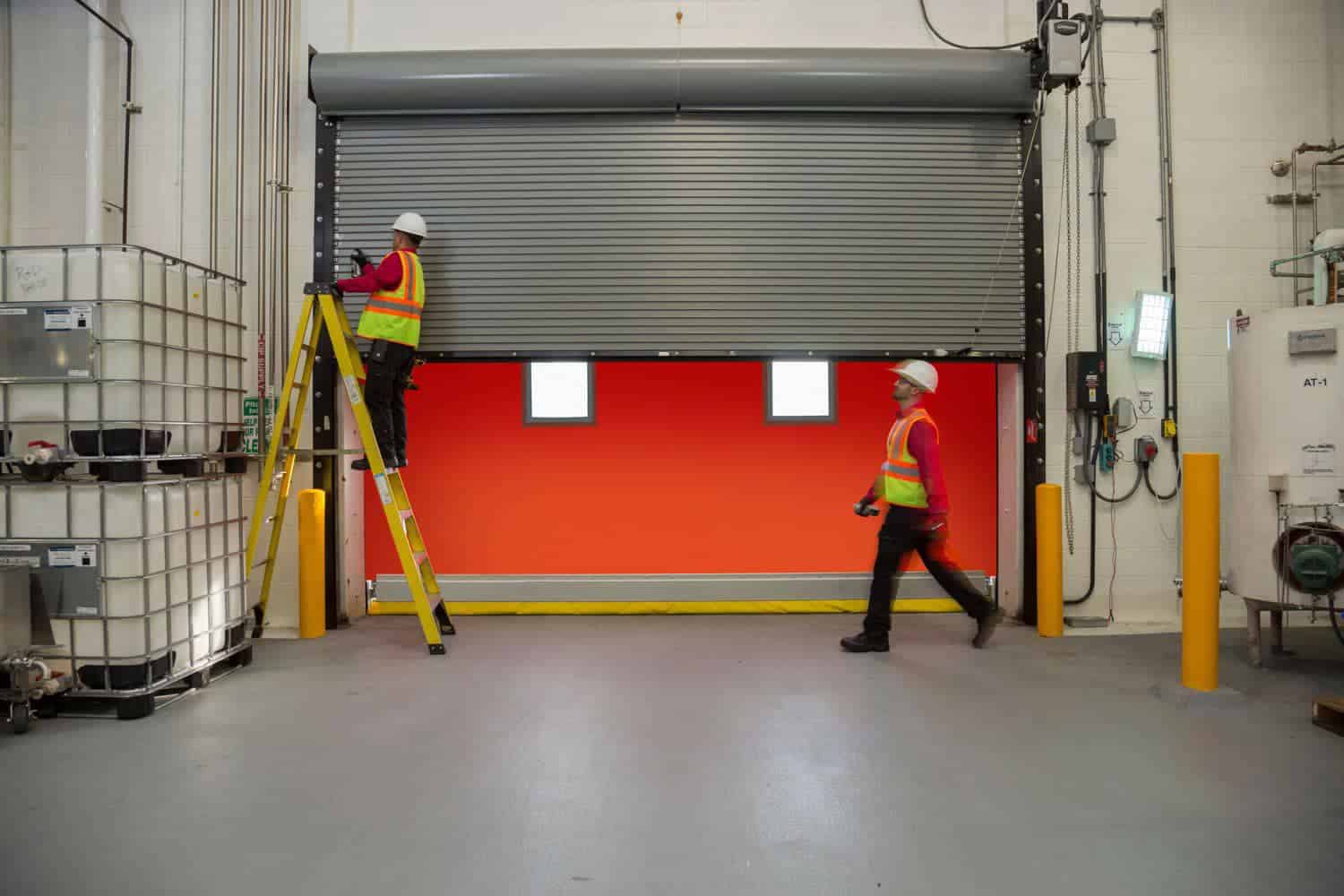

Why Loading Dock Door Maintenance Matters in 2025

A malfunctioning dock door is more than an inconvenience. Downtime can cost $10,000 per hour in lost productivity . Faulty doors also create serious risks: 25% of warehouse injuries happen at the dock area . Springs that snap, motors that stall, or sensors that misfire can cause accidents, spoil goods, and delay deliveries. For fast-moving logistics hubs, especially in regions like Abu Dhabi, every hour counts.

Common Issues with Loading Dock Doors

Mechanical wear and tear – Springs, rollers, and hinges eventually fatigue. A broken spring can instantly disable a door.

Electrical failures – Motors and control panels fail, leaving doors stuck mid-operation.

Sensor malfunctions – Misaligned or dirty sensors prevent proper closing or trigger false alarms.

Safety hazards – Free-falling doors, misaligned levelers, or broken restraints increase accident risk.

Traditional repairs are often reactive, meaning breakdowns strike at the worst possible time. Costs add up quickly through emergency callouts, overtime, and shipment delays.

The Role of AI in Loading Dock Door Repair

AI is changing maintenance from reactive to predictive.

- Predictive maintenance: Sensors track vibration, torque, or motor speed, and AI forecasts failures before they occur. Research shows predictive maintenance can cut downtime by 30–50% and reduce repair costs by 10–40% .

- Faster diagnostics: AI systems identify likely causes instantly, guiding technicians to the right fix.

- Cost savings: Planned service avoids expensive emergencies. Replacing a $300 spring before failure is far cheaper than a $3,000 breakdown with collateral damage.

How Sensors Improve Safety and Efficiency

Sensors are the eyes and ears of modern docks. By 2025, over 75 billion IoT devices are connected worldwide , and many are in warehouses.

- Damage detection: Vibration and strain sensors flag misalignments or worn parts before they fail.

- Safety sensors: Photo-eyes and radar stop doors if people or forklifts are detected.

- IoT-connected sensors: Real-time monitoring lets managers view door performance on dashboards or mobile apps.

Example: A warehouse in Abu Dhabi installed tilt sensors on door tracks. When unusual vibration was detected, bolts were tightened before a costly breakdown occurred.

Smarter Operations – AI and Sensors Together

When AI and sensors work in sync, operations become more reliable.

- Automated workflows: A dock door opens only when sensors confirm the truck is secured.

- Remote monitoring: Managers check all doors from a single dashboard, even off-site.

- Data-driven decisions: Analytics reveal which doors see the heaviest use, guiding better scheduling and preventive service.

This integration ensures compliance, minimizes downtime, and supports round-the-clock operations.

Cost Analysis – Traditional vs Smart Repairs

| Aspect | Traditional Repairs | Smart Repairs |

| Downtime | Frequent, unplanned, $10k/hr losses | Predictive, downtime reduced up to 50% |

| Costs | High emergency callouts | Lower, optimized scheduling |

| Safety | Higher accident risks | Sensors enforce safety |

| Equipment Life | Shorter lifespan | 20–40% longer life |

A mid-size warehouse reported saving over $20,000 annually by switching to predictive dock maintenance, with the system paying for itself within two years.

Challenges of Smart Loading Dock Repairs

- Upfront investment: Sensors and AI platforms add costs, though prices are falling.

- Technical expertise: Staff need training to use new systems effectively.

- Integration: Retrofitting older doors can be complex.

Practical advice: start small with a pilot on one or two docks, then expand as ROI becomes clear.

Future Trends Beyond 2025

The future of dock operations is even smarter:

- Integration with warehouse robotics – Doors sync with autonomous forklifts and AGVs.

- Self-healing doors – Systems automatically adjust tension or lubricate parts.

- Renewable energy docks – Solar-powered levelers and energy-efficient motors .

- AI-driven logistics networks – Data from thousands of docks feeding global optimization platforms.

With the AI in logistics market growing ~40% annually , innovations will only accelerate.

Conclusion

Loading dock door maintenance is no longer just about fixing breakdowns. By 2025, AI and sensors are transforming docks into predictive, safe, and efficient systems. Businesses that adopt smart solutions reduce downtime, cut costs, extend equipment life, and improve worker safety.